Chemical Cleaning of Equipment In Refineries and Petrochemical Plants

Standard Teknik

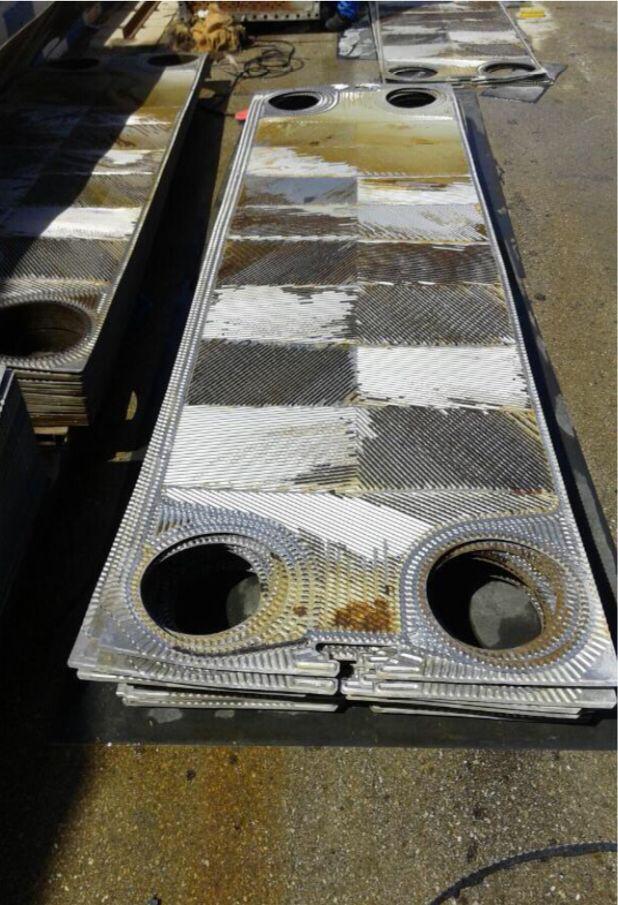

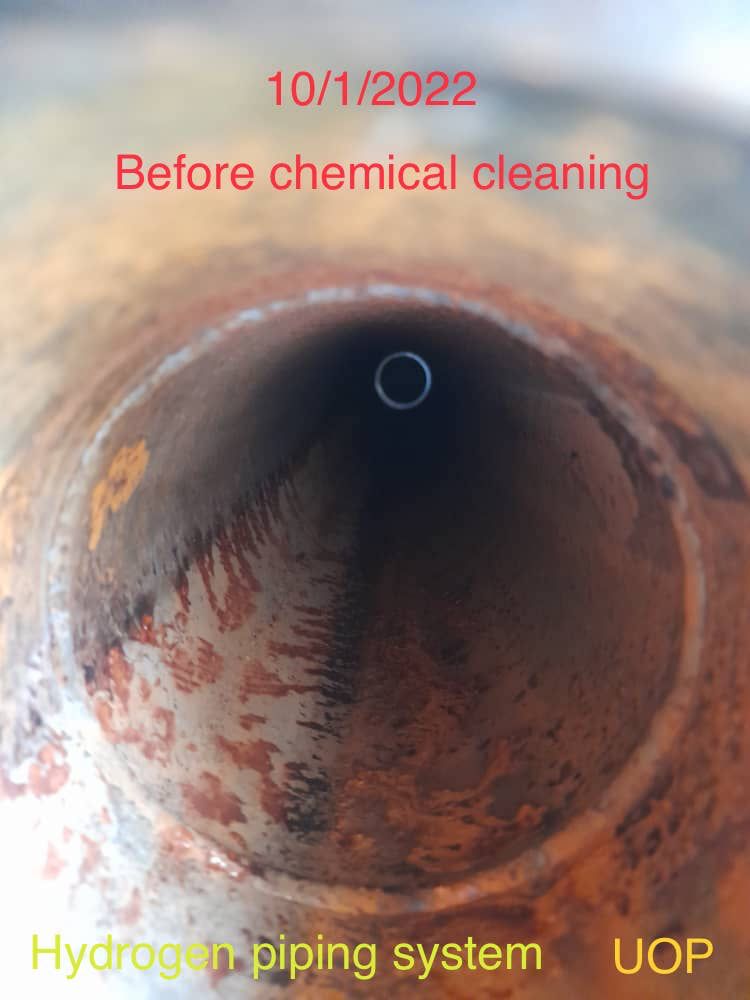

Chemical Cleaning and Flashing - Before

Standard Teknik

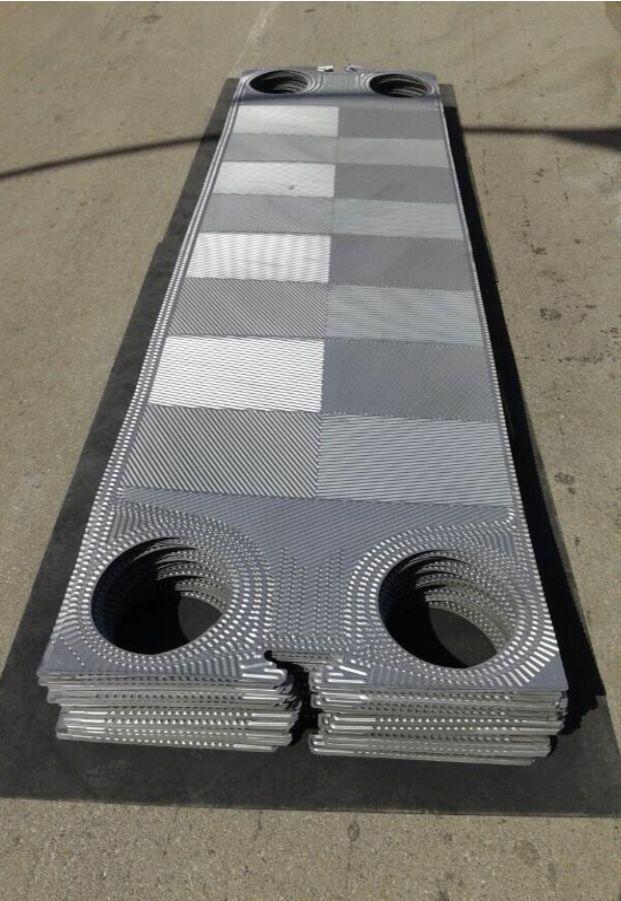

Chemical Cleaning and Flashing - After

Standard Teknik

Chemical Cleaning and Flashing - After

Standard Teknik

Chemical Cleaning and Flashing - Before

Standard Teknik

Chemical Cleaning and Flashing - Before

Standard Teknik

Chemical Cleaning and Flashing - After

Standard Teknik

Chemical Cleaning and Flashing

Standard Teknik

Chemical Cleaning and Flashing